| 8-5-08

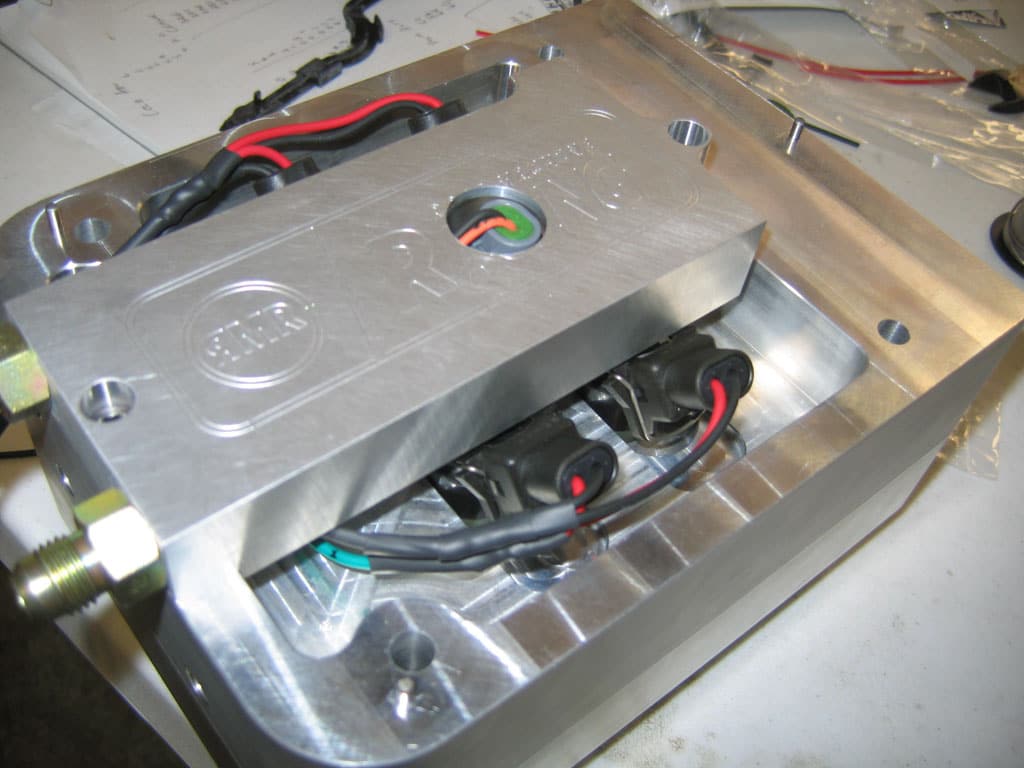

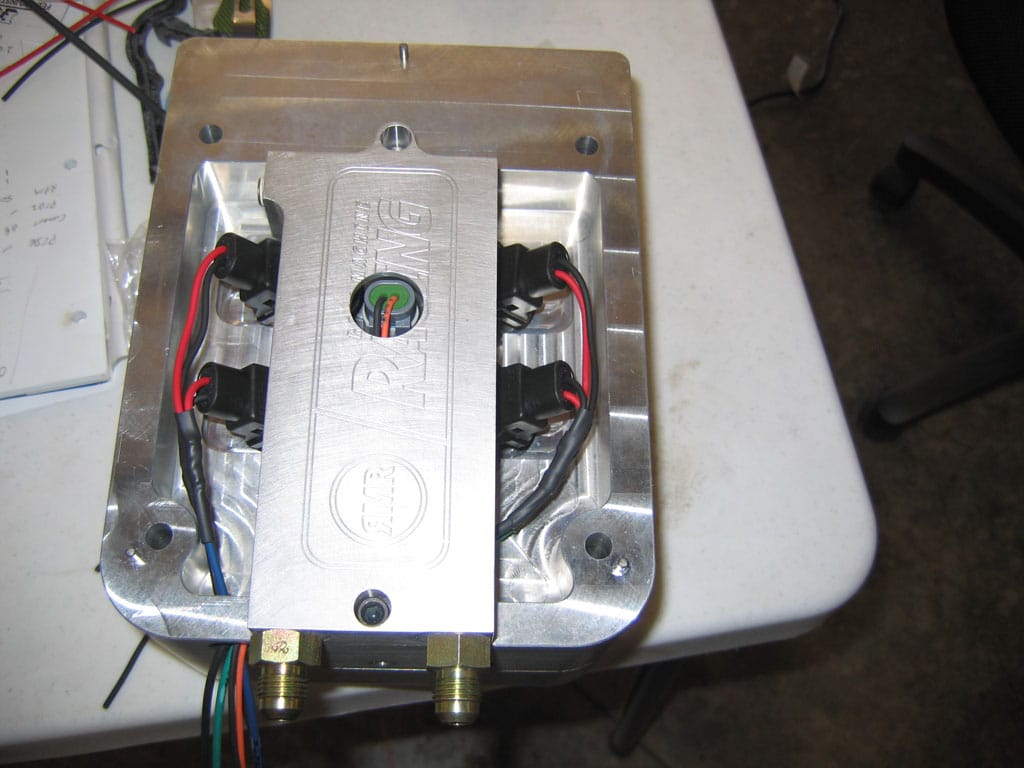

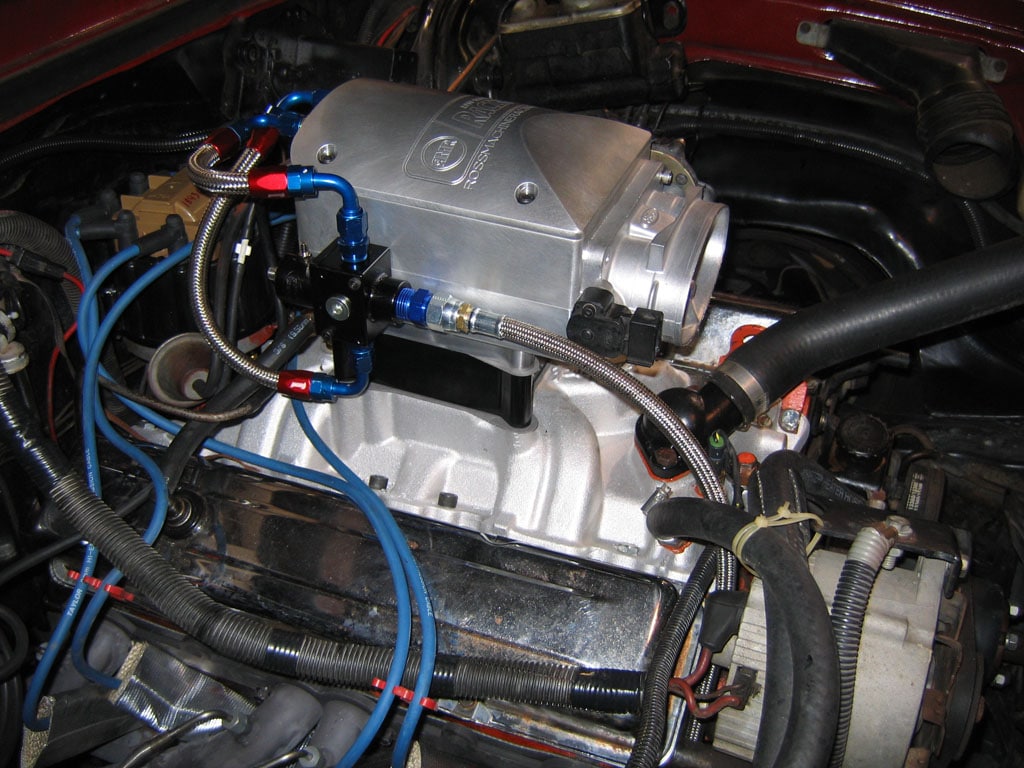

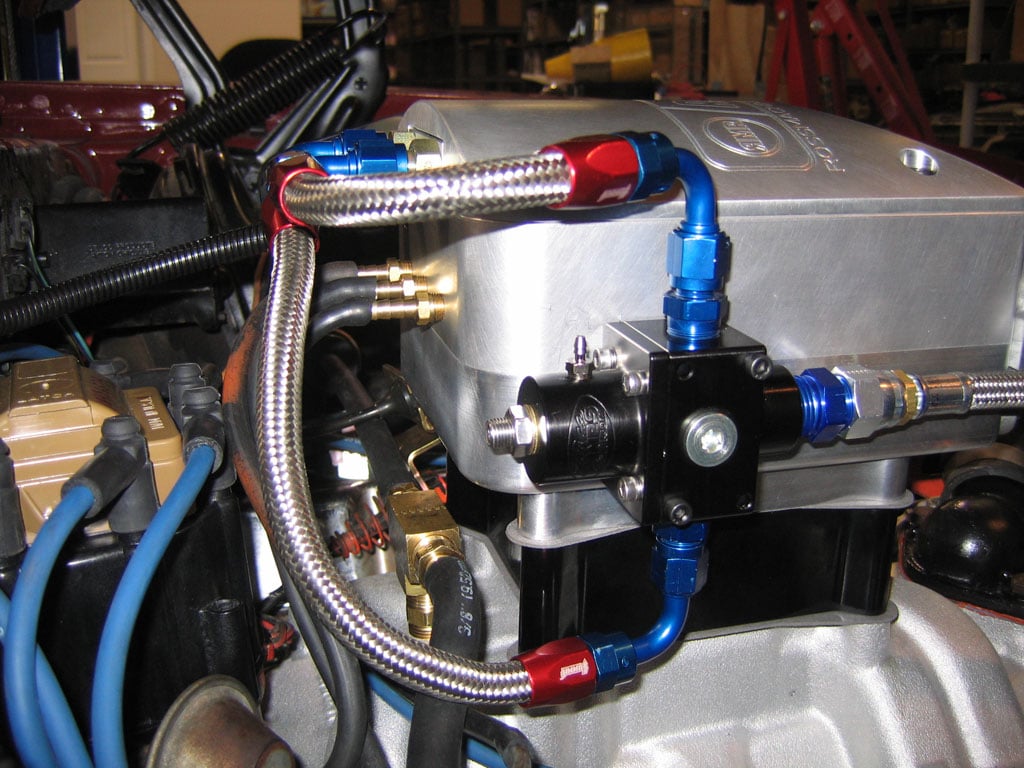

Quick update. Looks tough as you can see below. I put it up on a 2″ spacer to allow the inlet plumbing to clear the coolant plumbing. I fired it up yesterday for the first time, got it running fairly easily, but roughly. EGTs show very uneven cylinder temps (like 900*F) indicating uneven fuel distribution. I fought with it a bit and I want to do some more testing and see what I can come up with. I’m about to go put a fuel pressure gauge on it and make sure the RacePump and regulator are doing their jobs properly as it’s the first time I’ve used these bits too and I haven’t verified there is good consistent fuel pressure yet. I’ve got a logfile from my testing yesterday– you’ll need to download LogWorks from Innovate Motorsports support page. Here’s the logfile. Lemme do a bit more on this today and I’ll get back with my findings.

8-6-08 Yes it is possible to fire all injectors at once– right now they are set up to alternate and that could play a bit of a role so I’ll play with that later today probably. Right now, the issue seems to be worst at idle. It smooths out quite a bit when I free rev it though it’s not entirely gone. I was actually tempted to take it for a test run around the industrial park yesterday, shut it down for a minute and it wouldn’t start though, the heat vapor locked the fuel pump as I was running it returnless. I’m running a return line to the fuel tank now to alleviate that and I’ll get back to testing.

8-7-08 Update, and not with the best of news really. I’ve kept fighting with this setup trying everything I can come up with. I can get it to idle decent but not as smoothly as normal, and generally I’ve got a couple of cold cylinders indicating they’re either getting flooded with fuel, or they’re not getting enough fuel to fire and they’re no combustion in those cylinders at all. From the feel of it and the facts that the temps when this is happening may be extremely low, like just 40-50*F above ambient, I think it’s #2 (no combustion). I put it on the dyno yesterday and I’ve played with it a bit yesterday and today. I was able to tune the very low rpm cells at low-medium load, but if I try tuning at high load (even at low rpm columns still) it starts missing and AFRs jump around telling me air/fuel distribution is again an issue. I can’t tune it at all above about 2500 rpm or the missing gets so bad it’s scary. Air fuel ratio is a bit unpredictable due to the issues, you can see that overall it’s about right, while I’m just trying to rough it in I’m targeting 13.5-14.0 at low-medium loads which should run it just fine. But when I put any load on it at all it becomes clear it’s missing badly and that not all cylinders are firing evenly. I can sometimes watch when this happens and see the EGT of a particular cylinder start to drop off. So I’m holding it trying to rev past say 2300rpm with some load on it, and it’s spitting/coughing while I watch cylinder 6 take a dive in temp. Others must be struggling intermittently too or it would rev out better under load. The AFR is fine on average, but inconsistent to each cylinder. This is running a single plane Edlebrock Torker II manifold which had fairly good air/fuel distribution with the Holley carb. It ‘might’ help to try a dual plane manifold, and I have one, but I’m starting to run tight on time that I’m putting into this and I may need to resort to another option for the time being and get this car running. We’re trying to use the project for some website articles prior to a Hot Rod magazine article being released in a couple months and I need something completed to post.

|

Wanna learn more about how to tune EFI and Electronic Ignition? OF COURSE YOU DO!

|