You’ve either heard the term ‘Wasted Spark Ignition’ or seen it in the Megasquirt ignition settings in TunerStudio, but sometimes the concept can be tricky to grasp. If you’re running an aftermarket engine management system however, it’s something you should make sure to understand and use to your advantage.

What makes Wasted Spark better than a Distributor and Single Coil?

Let’s first examine what makes crank-fired ignition in general better than a traditional single-coil and distributor setup. In a word: accuracy. When we discuss ignition timing (aka ignition advance) we generally talk about it in degrees before top dead center, or deg BTDC. The ‘degrees’ are degrees of crankshaft revolution, but what we ACTUALLY care about is the position of the piston as it rises on it’s compression stroke. But since we can’t measure this directly and connecting rods don’t stretch (well, don’t stretch *that* much), crank angle is a very good indicator of piston position, and it’s something we CAN measure.

Distributor position however, is NOT anywhere near as good though, and here is why. Mechanical variance, aka SLOP. Mechanical variance/slop simply means that there are more pieces to the puzzle, all with their own tolerances, variances, stretch characteristics, temperature characteristics, etc. So– We’ve already dicussed the pistons through the wrist pins clearance, connecting rod stretch, rod bearing clearance, and crankshaft twist to get to our crank angle measurement. But if you’re getting engine position from a distributor, there are more links to that chain to consider– from there we then need to further go through the crank’s sprocket, any lash between the sprocket teeth and timing chain/belt, timing chain stretch, cam sprocket lash, sprocket to camshaft tolerance, camshaft twist, gear lash between the camshaft and distributor shaft, and finally any tolerance in the distributor itself.

Crank fired wasted spark ignition eliminates most of that ‘slop’, and provides for a more accurate crank angle to be reported to the ECU, while at the same time providing for more spark energy using multiple ignition coils rather than a single coil with the distributor.

If you’ve ever used a timing light to set the timing on a car with a distributor that uses points to trigger the coil, you’ve undoubtedly noticed how much the timing marks tend to ‘bounce around’ while doing so. That’s the combination of all of this driveline slop in action. In fact, it’s actually TWICE as bad; since the cam and distributor rotate at half the speed of the crankshaft, any error is therefore doubled when trying to infer back to crank angle. So in general moving from a cam or distributor-based estimation to a direct crank angle measurement gives you a huge boost in ignition timing accuracy. So then, how to we leverage that fact for a robust ignition system? That’s where wasted-spark comes in.

Keeping it simple and powerful with Crank Fired Wasted Spark

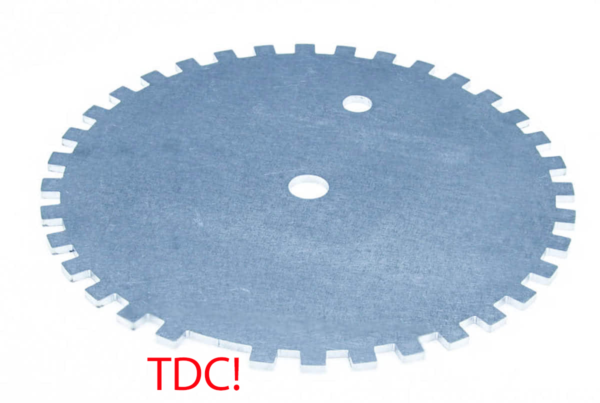

The key benefit of wasted-spark lies in the simplicity: it does NOT require ANY camshaft position information in order to run the engine! Whereas an old distributor setup needs to be installed/rotated to the correct position relative to the camshaft, and a sequential Coil-on-Plug ignition system (even when controlled based on crank angle) also needs feedback from the cam sensor to know which plug to fire. But wasted-spark (and also wasted-COP) ONLY needs the crankshaft position information in order to work. This is why missing-tooth crank trigger wheels are so popular, and are the one prerequisites for wasted spark:

Obviously the speed of the teeth (number of teeth/min) going past the sensor convey the speed at which the crankshaft is turning (RPM). But it’s that little gap, a ‘marker’ called a ‘missing tooth’ that is always in the same place on every rotation, that tells the ECU what POSITION the crank is at, and subsequently, what position the pistons are at too!

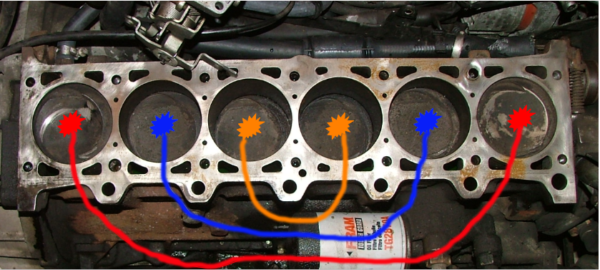

It’s as good as if we were looking at the pistons themselves without the head on:

Ok great, but how do we know which of the two pistons at TDC is on the compression stroke (and ready for ignition) and which one is instead on its exhaust stroke? Answer: Who cares?!? Wasted Spark Ignition is like Honey Badger, it just don’t give a crap. It just fires them both at the same time and it doesn’t matter! One has a combustible air/fuel mixture, and one doesn’t (just exhaust fumes). The ‘right’ one will combust, and the one on exhaust is just ‘wasted,’ but no harm no foul! The only thing left is to make sure you’re pairing up that single ignition signal to the correct pair of ‘matched’ cylinders. On the inline 6 in this example, you can see that’s 1&6, 2&5, and 3&4. You just need to follow the firing order: 1–5–3–6–2–4

So before even trying to sort out whether to trigger of of the rising or falling edge of your cam trigger, you can just go ahead and get the thing running first and just used wasted-spark!

With multiple coils to charge on each engine cycle, you dramatically increase the charge-time available for each coil before it fires. It’s the KISS principle of keeping it simple smartypants using a crank trigger without the need for a cam trigger, with an ignition performance benefit available over single coil/distributor at the same time! It’s win/win… and if you can drive… it could be win/win/win.

Here’s to winning!