Description

‘DarkStar’ Custom IAC Body for Jeep Stepper Motor Idle Air Controllers

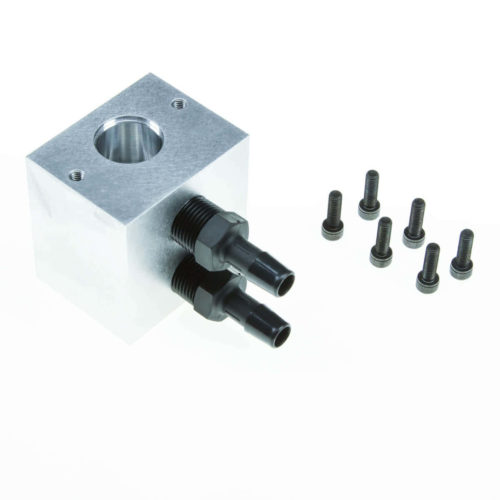

Custom machined IAC body for installing a IAC valve from a Jeep 4.0l motor, perfect for idle control with the MegaSquirt-II or later! Everything in the pictures is included, just add the IAC valve with o-ring and wire it up! 4 Mounting holes on the bottom/side depending on how you mount it with screws included. You should be able to find an existing bracket or spot on the firewall to bolt it to.

This valve body flows best if you plumb it so that pre-throttle air enters below the valve and exits above the valve to the manifold. This will give you a wider range of idle speed adjustment.

More Information:

- Dimensions are: 2.25″x 2.25″ x 1.75″ OR 57mm x 57mm x 44mm

- The barbed fittings are 3/8″ NPT.

- Valve bolt pattern is 1.8″ hole to hole with a 0.76″ ID hole

- Part Numbers for Compatible Valves (provided by DarkStar):

- Niehoff Part# 21774 (this is what was used in all testing)

- Wells AC320

The Standard AC151 and Borg Warner 21774 have the smaller pintle and may work on larger engines but are not guaranteed. This IAC body was designed to work with the “large pintle” version, where the pintle measures 0.490″ to 0.550″ at the largest point.

OEM Application of this valve: 1991-1997 Jeep Cherokee, Grand Cherokee, Wrangler and Comanche (including submodels) w/ 4.0L Inline 6 VIN S

Hose barbs are for 7/16″ (about 9.5mm) ID hose.

Customer reviews

Rated 5 out of 5 stars

5 reviews

4 stars

0

0 %

3 stars

0

0 %

2 stars

0

0 %

1 star

0

0 %

Only logged in customers who have purchased this product may write a review.

What is in the box?

- (1) Custom machined valve body, (2) NPT to hose barb adapters, and (6) mounting screws. Note that the stepper valve itself is not included. This is a mounting kit only.

What valves are compatible?

- OEM Application of this valve: 1991-1997 Jeep Cherokee, Grand Cherokee, Wrangler and Comanche (including submodels) w/ 4.0L Inline 6 VIN S. Part Numbers for Compatible Valves (provided by DarkStar):

- Niehoff Part# 21774 (this is what was used in all testing)

- Wells AC320

What MegaSquirt ECUs can control one of these valves?

- Any MegaSquirt-2, MegaSquirt-3, or MS3-Pro ECU can control a stepper idle valve. MS1 can not control a stepper. A Microsquirt can not control a stepper on its own, but can drive a stepper with external hardware. If you have an ECU that is not a MegaSquirt, please consult your ECU’s manufacturer.

Where is the valve body manufactured?

- The block is machined by DarkStar in the USA.

Does the valve work for forced induction applications?

- Yes. If your throttle body is downstream of the turbo or supercharger, you will want to plumb the upstream port on this block to a spot in between the throttle body and the turbo or supercharger to prevent boost leaks. The valve itself is not going to move under boost – the screw mechanism is not easily pushed back – but depending on the settings, the valve may not close fully under boost so as to return to a suitable idle faster.

What size thread is on the hose barb holes?

- They are 3/8″ NPT pipe thread.

5 reviews for Custom Idle Air Control Body for use with Jeep 4.0l IAC Valve